Aluminum Spandrel - Questions

Table of ContentsThe Basic Principles Of Secondary Glazing Panels Concrete Spandrel Panel Can Be Fun For AnyoneThings about Replacement Double Pane Glass PanelsNot known Incorrect Statements About Replacement Double Pane Glass Panels How Concrete Spandrel Panel can Save You Time, Stress, and Money.Excitement About Insulated Spandrel Panel

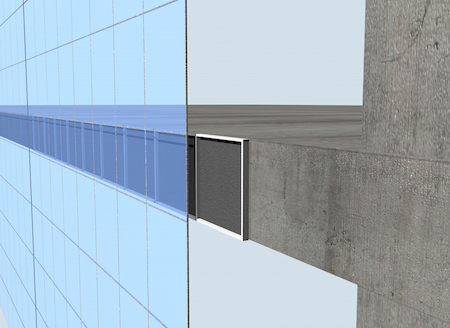

Periodically, there are issues connecting to having also much uncontrolled daytime, in some cases referred to as glow. The challenge is to pursue the highest possible noticeable light passage (VT) as well as the most affordable solar heat gain coefficient (SHGC) while not preventing the glass from being too reflective when seen from both the exterior as well as the interior, while regulating glare.The units should be totally set up in a manufacturing facility as well as shipped to the site for installment on the building. The units are positioned on the floorings, packed in pet crates, utilizing the tower crane and decreased right into area utilizing a smaller crane or lift possessed by the glazing service provider. The mullion measurements have a tendency to be somewhat bigger than a stick system as a result of their open area as contrasted to the tube form of a common stick drape wall surface section.

Units can be assembled in a factory while the architectural framework of the structure is being built. Where stick systems require numerous steps to put up as well as secure the wall, unitized wall surfaces arrive on the site entirely set up allowing the floors to be closed in quicker (insulated metal spandrel panels). Unitized systems likewise call for less space on site for layout hence giving an advantage for urban websites with room restrictions.

The Buzz on Replacement Double Glazing Panels Prices

The interlocking vertical mullions will typically have two interlacing legs. One leg will remain in the aircraft simply behind the glazing pocket and the other at the interior face of the mullions. The interlocking leg in the aircraft of the glazing pocket will certainly be secured by gaskets and also is the primary line of defense against water as well as air infiltration.

Equipments whose connecting legs lock likewise endanger the capacity of the system to suit movement. Some unitized designs are sensitive to small abnormalities in the spacing of adjacent modules; for example, if the component joints are slightly out of tolerance, gaskets may not be properly pressed and also moisture protection may suffer.

The four-way crossway describes the area where 4 nearby units meet. This is where field labor need to seal between nearby systems to accomplish a weather condition limited wall surface. The interlacing legs of the horizontal mullions are the most critical user interface of a unitized system. Water that infiltrates the interlocking vertical mullions drains pipes to the interlacing horizontals that should gather and also divert this water to the exterior.

Fascination About Gable Spandrel Panel

These upstanding legs have gaskets that secure versus the wall surfaces of the bottom horizontal. Some styles provide one upstanding leg that provides one line of protection versus air and also water infiltration. Much more robust systems will certainly offer 2 upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is set up on top of both surrounding devices as they are put up on the structure is typically called for.

The pile joint is the horizontal joint where systems from adjoining floors satisfy. Placing the stack joint at the sill of the vision glass (normally 30" over the flooring) will certainly minimize the dimension of the vertical mullions. This positioning uses the spandrel panel nhbc back span of the mullion over the anchoring factor at the piece to neutralize the deflection of the mullion listed below the slab (replacement double pane glass panels).

Specify that lab tests are to be performed at an AAMA Accredited Lab facility. Area Mock-up: For all drape wall surfaces, stock or custom, need building and testing of a field mock-up rep of the wall/window setting up. This is best arranged before the release of store illustrations for home window production, to make sure that there is a chance to make style adjustments based on the examination performance of the field mock-up.

Some Of Fire Rated Spandrel Panel

The information related to this area of the BEDG on the WBDG were developed by committee and are intended only as a way to highlight basic design and also building concepts only. Appropriate usage as well as application of the concepts showed in these information will differ based upon efficiency considerations and also ecological conditions special to every task and also, consequently, do not represent the last opinion or suggestion of the writer of each section or the committee participants in charge of the growth of the WBDG.

Continual metal sill blinking at the base why not find out more of the drape wall surface safeguards the wall framework listed below from leakage through the drape wall. Sill flashing must have upturned end dams and also totally sealed corners. Intermediate horizontal must be cried to the outside as well as protect against water from draining onto the head of the glazing unit listed below.

See This Report on Replacement Double Glazing Panels Cost

Gasket elevation must represent the curtain wall layout pressure. Exterior cover splice sleeves are mounted at the face of the stack joint during device area installment. Units are made as well as set up with straight and vertical clearance browse around this web-site spaces to permit for differential movement and suit building resistances. Pressure adjusted rainscreen gaskets create a main climate seal at the face of the unitized vertical stack joint in accordance with the horizontal rainscreen gasket at the unit sill below.

Spandrel glass adapters are utilized to decrease the depth of the glazing pocket to accommodate decreased account of spandrel glass. Spandrel glass adapters need to be totally bedded in sealer as well as incorporated with glazing pocket edge seals to protect against water leak from polishing pocket to building interior. Unit dimension of breeding head and also sill squeezed out profiles permits defined floor to flooring deflection at the pile joint.

Intermediate horizontals stop at the face of the upright device jamb participants at each end. Units are hung from the leading or face of the nearby floor or building framework making use of mated brackets and area used bolts with a minimum of clearance for accessibility as well as assembly. All links and brackets located within the systems protected or main climate seal areas are secured with proper sealant products during area installment.

Insulated Spandrel Panel Fundamentals Explained

non-heat-treated) or totally toughened up glass to remain in location up until it can be changed. Whether heat-strengthened or totally tempered, heat-treated glass products are produced in a comparable style as well as using the exact same processing devices. The glass is warmed to roughly 650 C (1200 F), then force-cooled to develop surface and also side compression.

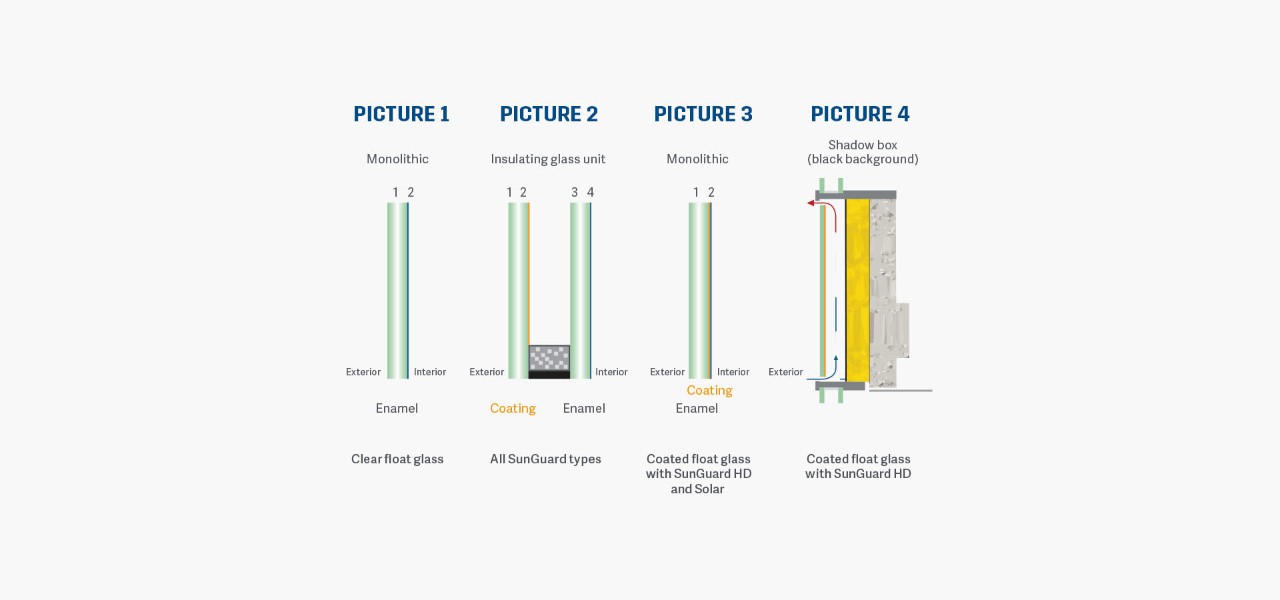

As suggested in Figure 1, insulation is often made use of combined with spandrel glass. When the insulation is to be used straight to the opacified surface area of the spandrel glass, it is essential to deal with a glass spandrel fabricator, along with the sticky as well as insulation providers, to make certain these items work with the opacifying product. replacement glazing panels.